Working Of Metal Stamping Process And It’s Methods

Metal Stamping is a system

of processes used in automotive industry to focus on metal manufacturing. The

process is to make the metal components into different moulded designs and

sizes. The process is mainly said to be the art of metal working.

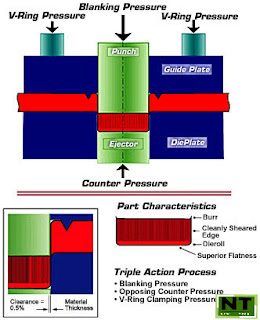

The process is mainly

responsible for a method of operation such as punching, blanking, piercing,

drawing, bending, flanging, embossing, forming and coining along with the

metals as needed. These stages of operations with stamping are carried out until

the metal forms desired shape and respective material is achieved.

The metals are being

cut, formed and shaped by feeding and pressing the metals between tonnage stamping

dies. This is majorly done in mass production industries and the parts are

developed with this process and it generally consumes low cost value.

Progressive Metal

Stamping is a form of metalworking method, in which the operations of stamping

are made with a single machine. Using a progressive Metal Stamping die and

reciprocating machine press stamping operation is done. The progressive metal

stamping die is placed into a reciprocating Metal Stamping press and as the

press moves up, the top die also moves along with it and this allows the

material to feed into press. And when the press moves down, the die closes and

performs the stamping operation. With each stroke of the press, the desired

metal is carried out from the die of Stamping On Metal.

In every automotive

industry, the quality assurance is being employed before and after the metal

stamping process activity. General requirements needed for quality assurance

separated into two categories. The pre-processing includes operator safety and machine

press precision and post-processing requirements includes product dimensions,

hardness and other quality conformances. And finally the requirement process is

ensured by the technology called stamping stimulation. The stamping stimulation

process prompts product defects and predicts lead time and production cost.